When we talk about power quality, we're really looking at how stable and dependable the electricity supply stays throughout a system. This matters a lot because unstable power can wreak havoc on all sorts of equipment. Problems like sudden voltage changes, those annoying harmonic distortions, plus electromagnetic interference are common when power quality drops. These issues don't just break things either they actually cost money through higher energy bills too. For certain sectors where electronics need to work flawlessly, maintaining solid power quality becomes absolutely essential. Think hospitals needing uninterrupted life support systems, factories running precision machines, or data centers keeping servers online without a hitch.

Inductors function as passive elements within circuits and contribute significantly to maintaining good power quality by keeping current stable. When electricity flows through these components, they actually store energy inside a magnetic field. This helps eliminate those annoying high frequency noises while cutting down on harmonic distortions, which are pretty much the main culprits behind bad power quality issues. The way inductors smooth out fluctuations in current means they stop sudden drops or spikes in voltage from happening, so whatever device is connected gets steady power all the time. Because of this, inductors remain essential for anyone looking to improve how clean and reliable their electrical power remains across different applications.

Inductors help cut down on electromagnetic interference (EMI) that messes with electronics and causes power issues. They work by blocking those pesky high frequency signals that get through other components. When built into EMI filters, these inductors act as shields against outside noise coming from things like motors running nearby or fluctuating power lines. Good design makes all the difference here since well-made inductors keep products compliant with FCC regulations while making sure power stays stable across different environments. For manufacturers working on medical equipment or industrial control systems, getting this right isn't just about meeting specs it's about keeping operations running smoothly day after day without unexpected shutdowns caused by stray electrical signals.

Mitigating harmonics stands out as one of the main reasons why inductors get so much attention in electrical engineering circles. Harmonics themselves are basically those pesky frequencies that mess with the clean shape of electrical power waves and lead to all sorts of inefficiency problems. When we talk about passive harmonic filters specifically, inductors shine because they can either block or at least reduce these troublesome frequencies quite effectively. Industrial settings where things like variable frequency drives and rectifiers run rampant really need good inductor solutions to keep their power quality intact. Getting rid of those harmonics means less wear and tear on expensive equipment while also making sure the whole power system runs smoother and more efficiently over time.

Choosing the correct inductor makes all the difference when it comes to getting good power quality out of any circuit. Air core inductors work best at high frequencies because they don't have that magnetic material inside which causes energy loss and can actually saturate under certain conditions. Engineers often go for these when dealing with situations that need small inductance numbers and minimal energy waste. On the flip side, magnetic core versions pack much more inductance into their design, so they shine in lower frequency scenarios while still improving overall power performance. We see these types commonly in industrial settings where stable inductance levels matter most throughout operation. When deciding between air core versus magnetic core options, designers typically look at what kind of frequencies they're working with and exactly how much power the system requires to function properly without issues down the line.

High current inductors are really important when dealing with big electrical flows while still keeping things efficient. When building these components, there are a few main considerations that matter a lot. The material choice makes all the difference here since lower resistance materials help keep losses down. Thermal control is another big deal too. Most engineers will either slap on some heat sinks or run fans over them just to stop things from getting too hot. And let's not forget about how tough these parts need to be. They get tossed around in power supplies, solar inverters, wind turbines, and factory equipment where conditions aren't exactly gentle. Get all these aspects right and the inductor stays reliable even when pushed hard through heavy duty operations.

Choosing the right inductor for a power system makes all the difference when it comes to getting good performance out of the setup. There are several important things to look at including how much inductance is needed, what kind of current it can handle, the operating frequency range, and what type of core material works best. These factors really matter because they determine whether everything will work together properly. When dealing with high frequency noise problems, air core inductors often come out on top since they don't suffer from saturation issues or energy loss in the core itself. On the flip side, magnetic core types tend to do better job cleaning up those pesky low frequency harmonics. Getting help from someone who knows their stuff or taking time to read through what manufacturers actually specify about their products helps narrow down options until finding something that fits specific requirements becomes possible.

Getting inductors right in power circuits takes some serious thinking ahead if we want good results. Where these components go matters a lot actually. Best practice? Put them close to wherever there's noise or harmonic interference happening in the circuit itself. This cuts down on problems affecting nearby parts quite dramatically. Maintenance checks shouldn't be an afterthought either. Regular inspections catch small issues before they turn into big headaches down the road. That kind of proactive approach keeps systems running reliably over time. When done properly, inductors can really shine, making those circuits work better overall while saving energy costs in the process. Most engineers will tell you this makes all the difference between just functional equipment and truly efficient power management solutions.

The C0402C103J3RACTU capacitor made by SACOH stands out as a great option for anyone needing reliable components that help move data efficiently while being kinder to the environment. What sets this part apart is its green credentials which many engineers look for when designing power systems these days. At just a small footprint but packed with durability, it fits right into today's electronics where every millimeter counts and performance simply cannot drop off. Another real plus point? This little workhorse does an excellent job cutting down on electrical noise and keeping power stable even under those tricky high frequency conditions we all deal with in modern circuit design. That means better overall system stability without having to sacrifice speed or functionality.

The H5TC4G63EFR-RDA IC from SACOH really shines when it comes to scaling up and delivering solid performance, especially in complicated power setups. What makes this chip special is how versatile it actually is. We're talking everything from factory automation systems all the way down to gadgets people use at home every day. The design works well across so many different industries because of this flexibility. And let's face it, power management is where this part truly kicks butt. It handles electricity distribution much better than most competitors while boosting how efficient entire systems run. For anyone dealing with electronics that need to balance power loads without wasting energy, this component offers real value on multiple fronts.

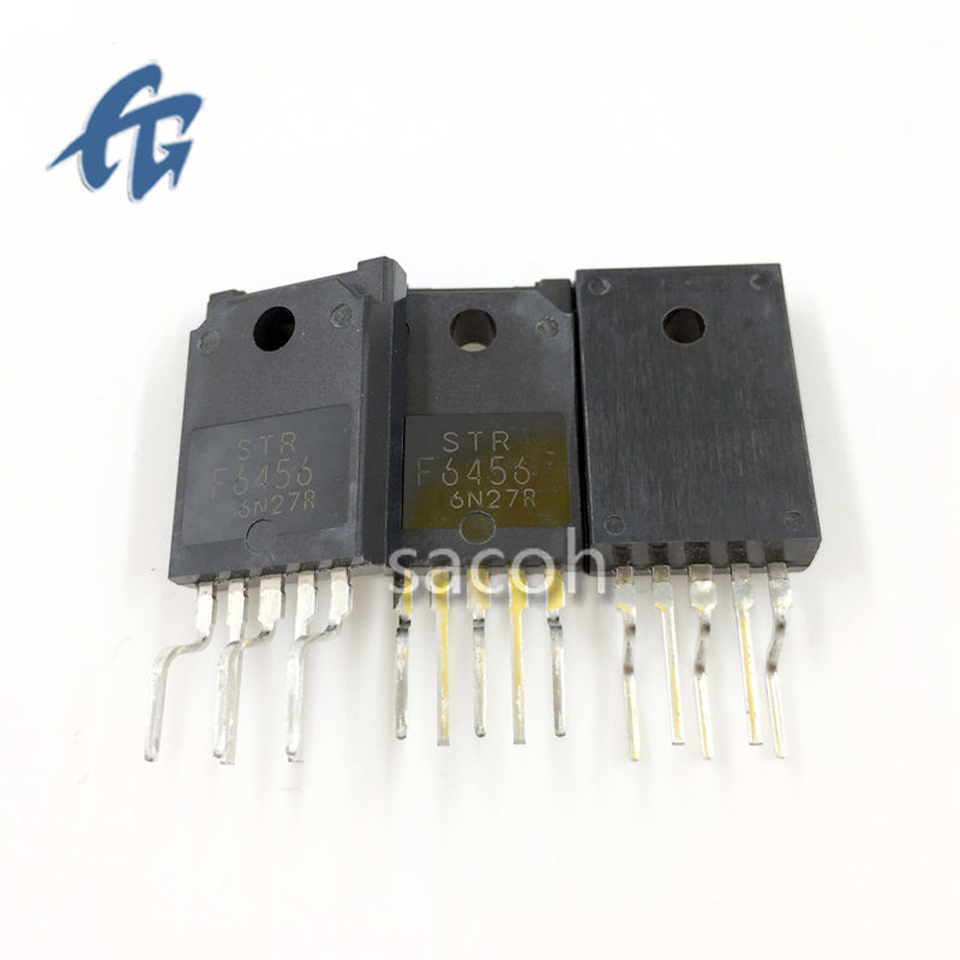

SACOH's STRF6456 microcontroller brings smart chip tech to the table, making a real difference in both power quality and overall system performance. What sets this device apart are its real time monitoring capabilities paired with adaptive control functions. Together these features work to cut down on wasted energy while keeping power usage at optimal levels. For anyone needing rock solid power management solutions, this controller shines particularly bright in fields like solar installations and grid management systems where precision matters most. The market seems ready for something like this as we push toward smarter energy solutions across various industries.

Inductors are really important components in smart grid systems where they use advanced tech to handle power flow better, cut down on energy loss, and bring renewable sources into the mix. When working within these modern grids, inductors basically keep things stable by controlling both voltage levels and current flow across the network, making sure electricity gets delivered reliably to end users without major disruptions. Looking ahead as smart grids develop further over time, we can expect inductors to take on an even bigger part in how power systems operate day to day. They'll be key players in allowing real time checks on system performance and adjusting controls automatically when needed. The improvements we see from this development do more than just make power cleaner and steadier though; they actually help connect wind farms, solar panels and other green energy options into our existing infrastructure much smoother than before, creating pathways toward a greener future for everyone involved.

Inductor design is seeing major changes lately, with engineers working hard to make them work better while taking up less space and handling heat more effectively. Some pretty cool stuff is happening too, like printing inductors using 3D printers and experimenting with materials at the nano level that could pack way more punch into smaller packages. These new approaches aren't just lab experiments anymore either. We're starting to see them show up in real world applications across different industries. For instance, automotive manufacturers are incorporating these advanced inductors into their electric vehicle models, while smart device makers find ways to fit them inside increasingly miniaturized IoT gadgets. What's really exciting about all this innovation is how it translates into tangible benefits: systems run cleaner, consume less power overall, last longer between replacements, and generally perform more reliably day after day. As companies continue pushing forward with greener technologies, these improvements in inductor design will play a crucial role in making our power management solutions both efficient and environmentally friendly.